Industrial Machine Vision Market Advances with Automation, AI, and Smart Manufacturing Adoption

"Executive Summary Industrial Machine Vision Market Size and Share Forecast

CAGR Value

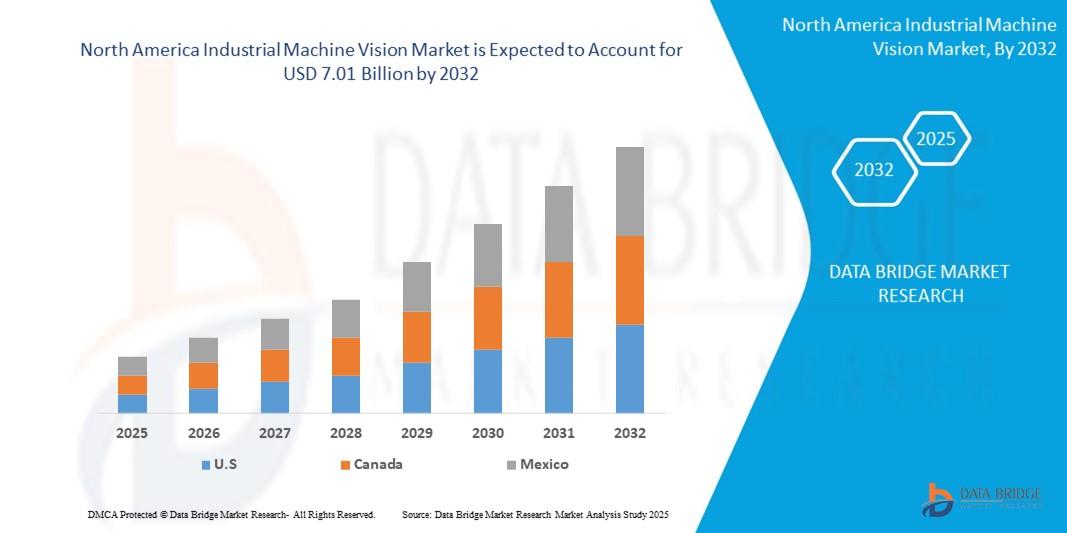

- The global industrial machine vision market size was valued at USD 11.29 billion in 2024 and is expected to reach USD 19.70 billion by 2032, at a CAGR of 7.21% during the forecast period

The Industrial Machine Vision Market report gives strength to the organization and makes better decisions for steering the business on the right track. A strong research methodology is used, comprising data models that include a market overview and guide, vendor positioning grid, market timeline analysis, company positioning grid, company market share analysis, standards of measurement, top-to-bottom analysis, and vendor share analysis. Moreover, only dependable sources such as journals, newspapers, company websites, and annual reports of the companies have been referred to collect the data which can be trusted confidently. It suits the requirements of small, medium, and large-sized businesses.

The superiority and transparency maintained in this Industrial Machine Vision report makes it attain the trust and reliance of the member companies and customers. Whereas competitive analysis studies of this market report gives ideas about the strategies of key players in the market. In addition, the identity of respondents is kept secretive and no promotional approach is made to them while analysing the data. Not to mention these topics have been carefully analysed with the best tools and techniques. The Industrial Machine Vision Market research report provides a comprehensive study on production capacity, consumption, import and export for all major regions across the world.

Gain clarity on industry shifts, growth areas, and forecasts in our Industrial Machine Vision Market report. Get your copy:

https://www.databridgemarketresearch.com/reports/global-industrial-machine-vision-market

Industrial Machine Vision Market Review

Segments

- Based on component, the global industrial machine vision market can be segmented into hardware and software. This segmentation is crucial as hardware components such as cameras, frame grabbers, optics, and lighting play a vital role in capturing and processing images, while software components provide the necessary algorithms for image analysis and interpretation.

- On the basis of product, the market can be categorized into PC-based machine vision systems, smart camera-based machine vision systems, and embedded vision systems. Each product type caters to specific industrial needs, with PC-based systems offering high processing power and flexibility, smart camera-based systems being compact and easy to integrate, and embedded systems providing real-time solutions for automation.

- Regarding application, the industrial machine vision market can be divided into inspection, measurement, identification, and positioning. Inspection applications involve quality control and defect detection in manufacturing processes, while measurement applications focus on accurate dimensioning and alignment. Identification applications include barcode reading and object recognition, and positioning applications deal with precise placement and alignment of objects.

Market Players

- Key players in the global industrial machine vision market include Cognex Corporation, Basler AG, Keyence Corporation, National Instruments Corporation, Teledyne Technologies, Inc., Omron Corporation, Sony Corporation, Allied Vision Technologies GmbH, and Intel Corporation. These companies are at the forefront of technological advancements in the machine vision industry, driving innovation and setting industry standards.

- Other notable market players are JAI A/S, Texas Instruments Incorporated, Baumer Holding AG, TKH Group, ISRA VISION AG, and FLIR Systems, Inc. These companies offer a wide range of machine vision products and solutions tailored to various industrial applications, ensuring high performance and reliability for their customers.

The industrial machine vision market is witnessing a rapid evolution driven by technological advancements and the growing demand for automation across various industries. One of the emerging trends in the market is the integration of Artificial Intelligence (AI) and deep learning algorithms into machine vision systems, enabling more advanced image processing capabilities and improving overall accuracy and efficiency. AI-powered machine vision systems can learn from data patterns, adapt to changing environments, and make real-time decisions, enhancing the capabilities of traditional machine vision technology. This integration of AI is revolutionizing industrial processes by enabling predictive maintenance, autonomous quality control, and intelligent defect detection.

Another significant trend in the industrial machine vision market is the increasing adoption of 3D vision systems. Traditional 2D machine vision systems are limited in their ability to accurately measure and inspect three-dimensional objects, leading to the rising demand for 3D vision technology. 3D machine vision systems utilize depth perception to capture detailed information about the shape, size, and orientation of objects, enabling more precise quality control, accurate measurements, and improved object recognition. Industries such as automotive, electronics, pharmaceuticals, and food and beverage are increasingly implementing 3D vision systems to enhance their manufacturing processes and ensure higher product quality.

Moreover, the shift towards Industry 4.0 and the Industrial Internet of Things (IIoT) is driving the demand for interconnected machine vision solutions that can seamlessly integrate with other smart manufacturing technologies. Machine vision systems are now being integrated into larger interconnected networks to enable data sharing, remote monitoring, and automated decision-making processes. By leveraging IIoT capabilities, industrial organizations can achieve greater operational efficiency, reduce downtime, and improve overall productivity. The convergence of machine vision with IIoT technologies is creating new growth opportunities for market players to develop innovative solutions that can meet the evolving needs of modern industrial environments.

Additionally, the increasing focus on sustainability and environmental consciousness is influencing the development of eco-friendly machine vision systems that consume less energy and reduce carbon emissions. Companies are investing in research and development to create energy-efficient machine vision solutions that align with sustainability goals and regulatory requirements. Green machine vision technologies not only help companies reduce their environmental impact but also contribute to cost savings and operational efficiency in the long run.

In conclusion, the industrial machine vision market is experiencing significant transformation driven by technological innovations, such as AI integration, 3D vision systems, IIoT integration, and sustainable practices. Market players are actively investing in research and development to stay ahead of the competition and meet the increasing demand for advanced machine vision solutions across diverse industrial sectors. As industries continue to adopt automation and digitization, the role of machine vision technology will become even more crucial in enabling efficient, reliable, and sustainable manufacturing processes.The industrial machine vision market is a dynamic and rapidly evolving sector driven by technological advancements and the increasing demand for automation in various industries. One key trend shaping the market is the integration of Artificial Intelligence (AI) and deep learning algorithms into machine vision systems. This integration enables enhanced image processing capabilities, improving accuracy and efficiency in industrial processes. AI-powered machine vision systems can learn from data patterns, adapt to changing environments, and make real-time decisions, unlocking new possibilities for predictive maintenance, autonomous quality control, and intelligent defect detection.

Another significant trend gaining traction in the industrial machine vision market is the adoption of 3D vision systems. Traditional 2D machine vision systems have limitations in accurately measuring and inspecting three-dimensional objects, leading to the rise in demand for 3D vision technology. 3D machine vision systems leverage depth perception to capture detailed information about object shape, size, and orientation, enabling precise quality control, accurate measurements, and improved object recognition. Industries such as automotive, electronics, pharmaceuticals, and food and beverage are increasingly embracing 3D vision systems to enhance manufacturing processes and ensure higher product quality.

Furthermore, the transition towards Industry 4.0 and the Industrial Internet of Things (IIoT) is fueling the need for interconnected machine vision solutions that can seamlessly integrate with smart manufacturing technologies. Machine vision systems are now being incorporated into larger interconnected networks to enable data sharing, remote monitoring, and automated decision-making processes. By harnessing IIoT capabilities, industrial organizations can achieve enhanced operational efficiency, reduced downtime, and improved overall productivity. The convergence of machine vision with IIoT technologies presents new growth avenues for market players to develop innovative solutions that cater to the evolving requirements of modern industrial settings.

Moreover, there is a growing emphasis on sustainability and environmental awareness, influencing the development of eco-friendly machine vision systems that prioritize energy efficiency and carbon footprint reduction. Companies are investing in research and development efforts to create sustainable machine vision solutions that not only align with environmental goals but also contribute to cost savings and operational efficiency in the long term. Green machine vision technologies play a vital role in helping companies minimize their environmental impact while enhancing their bottom line through reduced energy consumption and operational costs.

In conclusion, the industrial machine vision market is undergoing a significant transformation propelled by technological innovations like AI integration, 3D vision systems, IIoT integration, and sustainability initiatives. Market players are actively investing in R&D to innovate and meet the escalating demand for advanced machine vision solutions across diverse industrial sectors. As industries continue to embrace automation and digitalization, machine vision technology will play a pivotal role in enabling efficient, reliable, and sustainable manufacturing processes, driving growth and innovation in the market.

Uncover the company’s portion of market ownership

https://www.databridgemarketresearch.com/reports/global-industrial-machine-vision-market/companies

Nucleus is Data Bridge Market Research’s cutting-edge, cloud-based market intelligence platform that empowers organizations to make faster, smarter, data-driven decisions. Designed for strategic thinkers, researchers, and innovators, Nucleus transforms complex macroeconomic indicators, industry-specific trends, and competitive data into actionable insights through dynamic dashboards and real-time analytics. With capabilities spanning market access intelligence, competitive benchmarking, epidemiological analytics, global trade insights, and cross-sector strategy modeling, the platform unifies diverse datasets to help businesses identify opportunities, assess risks, and drive growth across regions and industries. Built on a powerful neural analytics engine, Nucleus bridges the gap between raw data and strategic execution, enabling users to visualize emerging trends, benchmark performance, and make informed decisions with confidence.

Get More Detail: https://www.databridgemarketresearch.com/nucleus/global-industrial-machine-vision-market

Structured Market Research Questions for Industrial Machine Vision Market

- What is the present size of the global Industrial Machine Vision industry?

- What annual growth rate is projected for the Industrial Machine Vision sector?

- What are the main segment divisions in the Industrial Machine Vision Market report?

- Who are the established players in the global Industrial Machine Vision Market?

- What geographic areas are explored in the Industrial Machine Vision Market report?

- Who are the leading manufacturers and service providers for Industrial Machine Vision Market?

Browse More Reports:

Global Water Treatment Chemicals Market

Global Scented Candle Market

Global Ceramics Market

Europe Japanese Restaurant Market

Global Smart Fleet Management Market

Global Tuna Market

Global Tote Bags Market

Global Gemstones Market

Global Japanese Restaurant Market

Global Hypochlorous Acid Market

Global Toothbrush Market

Global Cataracts Market

Global Wire and Cable Market

Global Plant-Based Food Market

Global Tomatoes Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness