Are Your Cleanroom Standards Maximized with Yd Clean Room Door

In industries where precision, hygiene, and contamination control are critical, a Clean Room Door from Yd-Purification has become an essential component in facility design. From pharmaceuticals to electronics assembly, maintaining a controlled and sterile environment is vital. How can the right door system ensure both safety and operational efficiency in such sensitive settings?

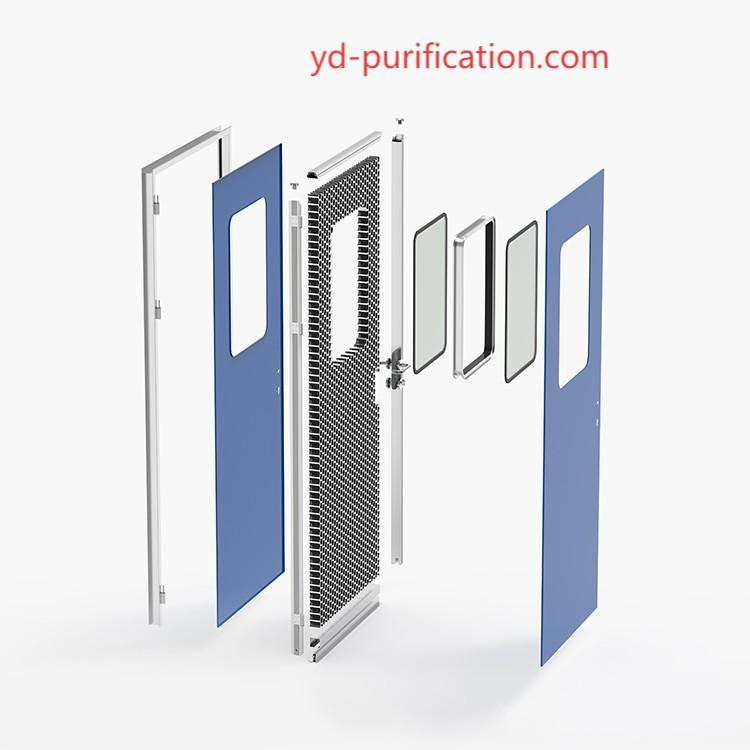

Modern cleanrooms require careful engineering and thoughtful design. Doors are not mere entry points; they regulate airflow, prevent particle intrusion, and support strict sanitation standards. High-quality materials combined with meticulous construction ensure durability, maintaining airtight seals under constant use. This reliability allows facilities to operate without frequent interruptions while upholding stringent safety and hygiene protocols.

Adaptable design is another key consideration. Each facility has unique layouts, workflow patterns, and compliance obligations. Doors that integrate smoothly with existing structures and environmental control systems facilitate efficient movement while minimizing the risk of contamination. Smooth surfaces, ergonomic handles, and optional automation reduce human contact, maintaining a sterile atmosphere and supporting operational continuity.

Long-term performance is enhanced through careful attention to durability and maintenance. Doors engineered for longevity reduce the need for replacements and sustain consistent performance. Regular inspections and professional support ensure ongoing compliance with hygiene standards. A balance of functionality and aesthetic appeal also provides confidence to management and staff, reinforcing the integrity of controlled environments.

Energy efficiency and sustainability are increasingly important. Well-insulated and tightly sealed doors help maintain temperature and humidity levels without overburdening climate control systems. This contributes to environmentally conscious operations and supports stable conditions for sensitive processes. Additionally, fire-resistant materials, emergency access mechanisms, and intuitive controls provide added protection for both personnel and critical products.

Selecting a reliable manufacturer ensures that these performance standards are met. Yd has built a reputation for precision, customization, and consistent quality. By investing in thoughtfully engineered doors, facilities achieve a combination of safety, reliability, and operational efficiency. Are you ready to elevate your cleanroom environment and protect essential processes? Explore the range of Clean Room Door solutions at www.yd-purification.com/product/cleanroom-doors/ and see how your facility can benefit from these advanced systems.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness