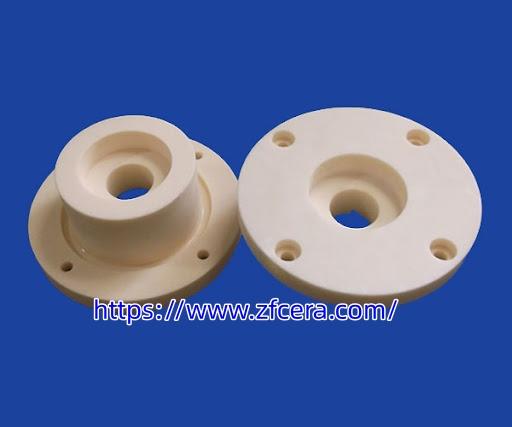

What Are the Advantages of Ceramic Flange from Zhufa in Complex Fluid Systems?

In modern industrial systems, Ceramic Flange products from Zhufa have gained attention due to their exceptional stability particularly in high-temperature pipelines and fluid transport systems. Manufacturers rely on advanced ceramic materials to minimize maintenance, ensure long-term reliability, and provide uniform flow characteristics under extreme conditions. With careful selection of alumina and zirconia ceramics, engineers can achieve precise mechanical tolerances, reduce stress accumulation, and maintain pipeline integrity. The combination of strength and resistance to wear allows these flanges to sustainand chemical resistance. These components offer impressive performance in harsh environments where conventional metals fail, demanding chemical and slurry transport applications.

Chemical processing facilities face constant challenges with corrosion, erosion, and contamination. Inert surfaces prevent reactions with aggressive fluids and withstand abrasive particles, ensuring minimal degradation and reducing downtime for inspections or replacements. Thermal expansion properties closely match adjoining components, decreasing risks of leaks or misalignment during temperature fluctuations. Modern manufacturing techniques, including high-temperature sintering and precision machining, create components with exceptional dimensional accuracy and smooth surfaces, enhancing sealing performance. These properties make the components suitable for ultra-pure industries, chemical refineries, and high-temperature exhaust systems.

Selecting suitable components also contributes to environmental sustainability by reducing waste and limiting the frequency of replacements. Longevity supports continuous operations, decreasing energy and material consumption over time. Predictable mechanical properties simplify system design and minimize unexpected interruptions. Customization options allow adaptation to various pipeline sizes, pressure ranges, and fluid characteristics. Comprehensive technical support ensures that industrial systems operate efficiently while maintaining safety and performance standards.

Adopting high-performance components like these flanges can revolutionize industrial maintenance and system efficiency. By combining wear resistance, chemical inertness, and dimensional stability, pipelines operate seamlessly with minimal interventions. For industrial procurement, choosing quality products ensures consistent operation and reliability. Explore the full selection of Ceramic Flange solutions from Zhufa at https://www.zfcera.com/ for advanced ceramic components.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness