Explore qhpreformmould Plastic Preform Moulds for Stable Processing Windows

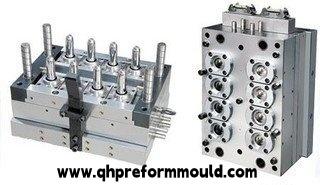

Packaging producers need equipment that delivers repeatable accuracy while handling demanding schedules in competitive markets. Plastic Preform Moulds form the critical link between raw resin and finished bottles, creating intermediate shapes with exact dimensions and flawless surfaces through injection processes. The structure incorporates advanced gate designs and cooling layouts that promote uniform material flow and rapid solidification, yielding preforms suitable for high-speed stretching and blowing later.

Designers emphasize balanced runner systems that distribute melt evenly to every cavity, eliminating cold spots or overpacking. Hot runner technology maintains consistent temperatures at nozzles, reducing drool and stringing between shots. These elements work together to support stable processing windows across varying ambient conditions.

Floor staff value the practical handling these moulds offer during routine operation. Heavy-duty tie bars provide rigid support under closure forces. Guided ejection plates ensure gentle part release without damage. Clear access points facilitate thorough cleaning after resin changes.

Management teams recognize the strategic advantages in production planning. Modular core sets allow quick conversion between different preform weights or thread styles. Durable plate construction withstands millions of cycles with proper care. The investment protects against frequent replacements while enabling capacity growth.

Resource management improves through precise shot control and minimal flash generation. Lower reject rates contribute to cleaner facilities and reduced resin consumption. The entire workflow supports lean manufacturing principles effectively.

International bottlers employ these moulds across beverage, food, and household product lines. Material-specific adjustments accommodate engineering resins alongside commodity grades. Best practices circulate through industry channels, enhancing overall application knowledge.

Detailed views highlight mirror-like cavity finishes that transfer directly to preform exteriors. Real-world installations demonstrate reliable performance in multi-shift environments.Wear-resistant coatings on critical areas extend service intervals significantly. Integrated sensors monitor key parameters for preventive maintenance scheduling.

Focused on delivering functional precision, qhpreformmould builds moulds meeting rigorous packaging standards worldwide. Examine options designed for seamless integration into existing lines.Plants aiming for operational excellence select tooling that combines robustness with adaptability. Broad choices cover various neck finishes and volume requirements. Consult technical specialists to determine ideal configurations.

Finally, access comprehensive mould resources and professional guidance at Taizhou Qihong Mold Co., Ltd.: https://www.qhpreformmould.com/ where precision drives packaging innovation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness