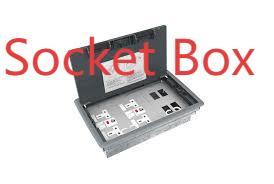

Nante Electrical Socket Box Field-Ready Solutions

For resilient outdoor and industrial installations, teams expect the Electrical Socket Box to provide watertight protection and straightforward access for servicing personnel, and specifiers also require the Electrical Socket Box to integrate neat cable entry and secure mounting so that routine maintenance is fast and predictable. This article outlines practical design priorities, material choices, installation best practices, modular options, and maintenance strategies that keep socket-box deployments safe and economical over their lifecycle.

Core design priorities for reliable socket boxes

Start with the functional brief: number of outlets or terminal points, protective device integration, and required ingress rating. Designers should prioritize simple internal layouts that separate incoming feeders from outgoing circuits, allow clear labeling, and preserve minimum bend radii for cables. Mechanical retention — captive fasteners, strong hinges, and tamper-resistant latches — reduces accidental damage and theft. Finally, designers must ensure the box supports common mounting hardware so installers don’t need custom adapters on site.

Materials and corrosion-resistant engineering

Material selection directly affects longevity. Metal enclosures like stainless steel and aluminum provide mechanical strength and electromagnetic shielding, while high-performance polymers and fiberglass composites offer inherent corrosion resistance and insulation advantages. For coastal, washdown, or chemical environments, specify appropriate coatings and hardware finishes (such as stainless fasteners and salt-spray-tested finishes). Gasket materials should resist compression set and resist the local temperature range to maintain continuous sealing performance.

Installation techniques that preserve sealing and safety

A large share of field failures come from improper cable entry or neglected grounding. Use correctly sized cable glands, conduit adapters, or integrated cable-entry plates that maintain the box’s rated protection. Torque terminal screws to manufacturer values and secure strain relief so vibrations do not loosen connections. Ensure protective earth connections are made before energizing and that bonding conductors follow local fault-current sizing rules. Good on-site documentation — circuit labelling and a commissioning checklist — prevents mistakes during later interventions.

Nante Modular Socket Box Options And Field Benefits

Modularity reduces downtime and spare-part complexity: standardized mounting rails, removable insert frames, and interchangeable outlet modules let technicians swap only the failed portion rather than the full enclosure. Nante’s modular approach enables prewired replacement modules and simplified spare inventories, which is particularly valuable for rental fleets, events, or multi-site operations. Modular kits also speed upgrades, allowing new device types to be added without panel redesign.

Inspection, monitoring, and lifecycle planning

Regular inspections and simple electrical tests extend service life and improve safety. Visual checks should focus on gasket condition, latch integrity, and signs of moisture ingress or corrosion. Periodic torque verification and contact-resistance testing catch developing problems before they become failures; thermal scans are especially effective at revealing hot connections under load. Consider adding basic monitoring — temperature or current sensors — to trigger maintenance only when needed, enabling condition-based rather than calendar-based servicing.

In practice, choosing the right socket box reduces both immediate installation headaches and long-term operating costs. Prioritize ingress-rated designs, durable materials, and modular replacements so your installations stay serviceable and safe. For product options, accessory kits, and purchasing information, see https://www.nante.com/product

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness