Shanghai MSD and Industry-Specific Inflatable Solutions

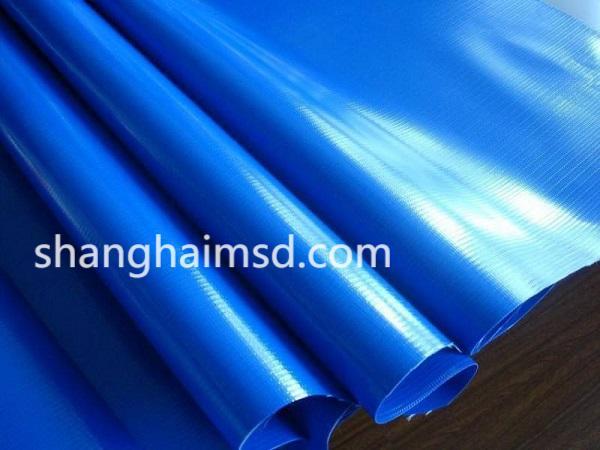

Inflatable products are expected to maintain consistent performance across repeated cycles of inflation, compression, and environmental exposure, a requirement that places strong emphasis on material control from formulation through finishing. During early material evaluations, designers often recognize that PVC Inflatable Fabric functions as a dynamic structure rather than a static sheet, meaning its behavior is shaped as much by processing decisions as by raw material selection.

The polymer formulation stage establishes the baseline for mechanical response. Flexible PVC compounds used for inflatable applications are engineered to balance softness with load-bearing capability. Plasticizers determine elasticity and folding behavior, while stabilizers protect against thermal degradation during processing. The interaction between these additives governs how the material reacts to welding temperatures, storage conditions, and prolonged internal pressure.

Fabric reinforcement introduces an additional layer of complexity. The textile substrate is not merely a strength provider but a directional control element. Warp and weft orientation influence elongation patterns, affecting how inflatable chambers expand under pressure. Selecting an appropriate fabric structure helps reduce distortion and ensures that expansion occurs uniformly rather than unpredictably.

Manufacturing processes translate these material choices into functional performance. Coating and lamination methods are adjusted to achieve stable adhesion between PVC layers and textile reinforcement. Precise control over coating thickness contributes to predictable air retention and surface durability. Variations at this stage can lead to uneven stress distribution, increasing the likelihood of seam fatigue during use.

Thermal processing parameters deserve particular attention. Inflatable materials must tolerate repeated exposure to welding temperatures without surface scorching or internal weakening. Controlled melt behavior allows seams to form securely while preserving adjacent material integrity. This balance is essential for applications requiring complex shapes or multiple air chambers, where seam density is high.

Surface treatment is another important factor influencing downstream performance. Smooth, low-friction finishes reduce wear during folding and transport, while textured surfaces may enhance grip or aesthetic appeal. These treatments must remain compatible with bonding and welding processes, ensuring that decorative or functional finishes do not compromise structural reliability.

Testing frameworks provide measurable insight into how process decisions affect real-world use. Tensile and tear resistance tests evaluate base strength, while seam strength testing focuses on bonded zones under load. Fatigue testing simulates repeated inflation cycles, revealing long-term deformation tendencies. Environmental exposure tests assess how material properties shift when subjected to temperature variation, humidity, or light exposure.

Application-driven performance tuning is increasingly important as inflatable products diversify. Water-based inflatables demand controlled buoyancy and moisture resistance, while land-based structures may prioritize abrasion tolerance and dimensional stability. Advertising inflatables often require consistent surface appearance alongside mechanical reliability. These varying requirements push manufacturers to fine-tune materials rather than rely on generic specifications.

Shanghai MSD contributes to this optimization process by emphasizing material consistency and technical alignment with customer fabrication methods. By coordinating compound characteristics, fabric selection, and surface treatments, the company supports inflatable manufacturers seeking stable production outcomes and reduced material variability across projects.

Logistics considerations also influence material design. Inflatable fabrics must retain flexibility after extended storage and transport. Resistance to plasticizer migration and surface blocking ensures that materials remain workable upon arrival at fabrication sites. These characteristics, though less visible, play a significant role in maintaining efficient production workflows.

As inflatable product designs become more complex, material evaluation increasingly occurs alongside prototype fabrication rather than in isolation. Feedback loops between testing, processing, and final application help refine material specifications to meet evolving demands. This integrated approach highlights the importance of viewing inflatable materials as engineered systems rather than simple coated fabrics.Further technical discussion on formulation balance, processing logic, and application versatility can be explored through Shanghai MSD’s dedicated resource at https://www.shanghaimsd.com/news/what-is-pvc-inflatable-fabric-everything-you-need-to-know.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness