-

Новости

- ИССЛЕДОВАТЬ

-

Страницы

-

Группы

-

Мероприятия

-

Статьи пользователей

-

Offers

-

Jobs

-

Форумы

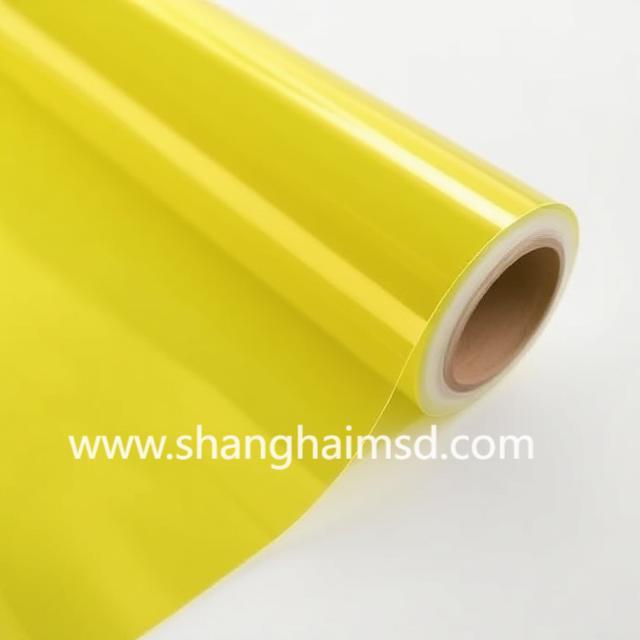

Shanghai MSD TPU Compound Film: Advanced Solutions for Industry

In modern manufacturing, TPU Compound Film has become a cornerstone for industries that demand materials combining flexibility, strength, and durability. Its unique thermoplastic structure allows engineers to achieve solutions that outperform standard plastic sheets, offering enhanced resilience, wear resistance, and multifunctional capabilities.

The key to the material’s versatility lies in its molecular architecture, which combines soft and hard segments within the polymer. This dual-phase structure provides elasticity while maintaining structural integrity, allowing the composite to withstand repeated stretching, bending, or compression without permanent deformation. Layered assemblies further enhance performance, offering superior puncture resistance, tear strength, and environmental stability compared to single-layer alternatives.

Production of TPU-based laminates involves precise control of temperature, pressure, and lamination speed to ensure consistent adhesion and uniformity. Advanced manufacturing techniques, such as extrusion, calendaring, and hot lamination, allow manufacturers to create films tailored for specific properties, including barrier performance, optical clarity, surface smoothness, and mechanical flexibility. Such control enables the production of materials suitable for applications ranging from medical protective coverings to industrial protective layers.

Seamless joining methods, including heat welding, ultrasonic bonding, and high-frequency sealing, enhance the utility of the film by enabling strong, airtight, or waterproof connections without additional adhesives. This makes the material ideal for products that must contain fluids, withstand pressure, or maintain integrity in harsh environments. Furthermore, the films are compatible with cutting, printing, and embossing, supporting complex designs while retaining performance characteristics.

The applications of TPU-based films span multiple sectors. In healthcare, the material’s chemical resistance, easy-clean surfaces, and biocompatibility make it suitable for protective covers, equipment casings, and hygiene-critical components. Industrial applications benefit from its wear resistance, chemical stability, and flexibility, making it a reliable choice for linings, flexible hoses, and damping layers. In recreational and outdoor equipment, its UV resistance, waterproof nature, and ability to perform in extreme temperatures enhance the durability of tents, inflatables, and protective gear.

Rigorous testing is essential to guarantee reliable performance. Mechanical tests such as tensile strength, elongation, and tear resistance measure durability under stress. Environmental assessments, including UV exposure, thermal cycling, and chemical resistance tests, simulate real-world conditions, ensuring long-term functionality. For applications involving containment or sealing, hydrostatic and leak tests confirm material integrity. These evaluations assure that the films can meet stringent performance requirements across a broad spectrum of uses.

Sustainability and longevity further enhance the appeal of these composites. Avoiding solvent-based adhesives reduces chemical impact, and the extended service life of the material decreases replacement frequency. The combination of robust performance, design flexibility, and eco-conscious advantages positions TPU-based laminates as a material of choice for forward-thinking manufacturers.

Shanghai MSD International Trade provides high-quality TPU laminates, supporting companies in selecting films that meet exacting performance and regulatory requirements. Their experience enables businesses to leverage advanced polymer technologies, producing reliable, long-lasting products across diverse industries.For further details on the composition, processing techniques, and application versatility of TPU-based laminates, visit Shanghai MSD at https://www.shanghaimsd.com/news/the-composition-and-versatility-of-tpu-compound-film.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness