-

Fil d’actualités

- EXPLORER

-

Pages

-

Groupes

-

Evènements

-

Blogs

-

Offres

-

Emplois

-

Forums

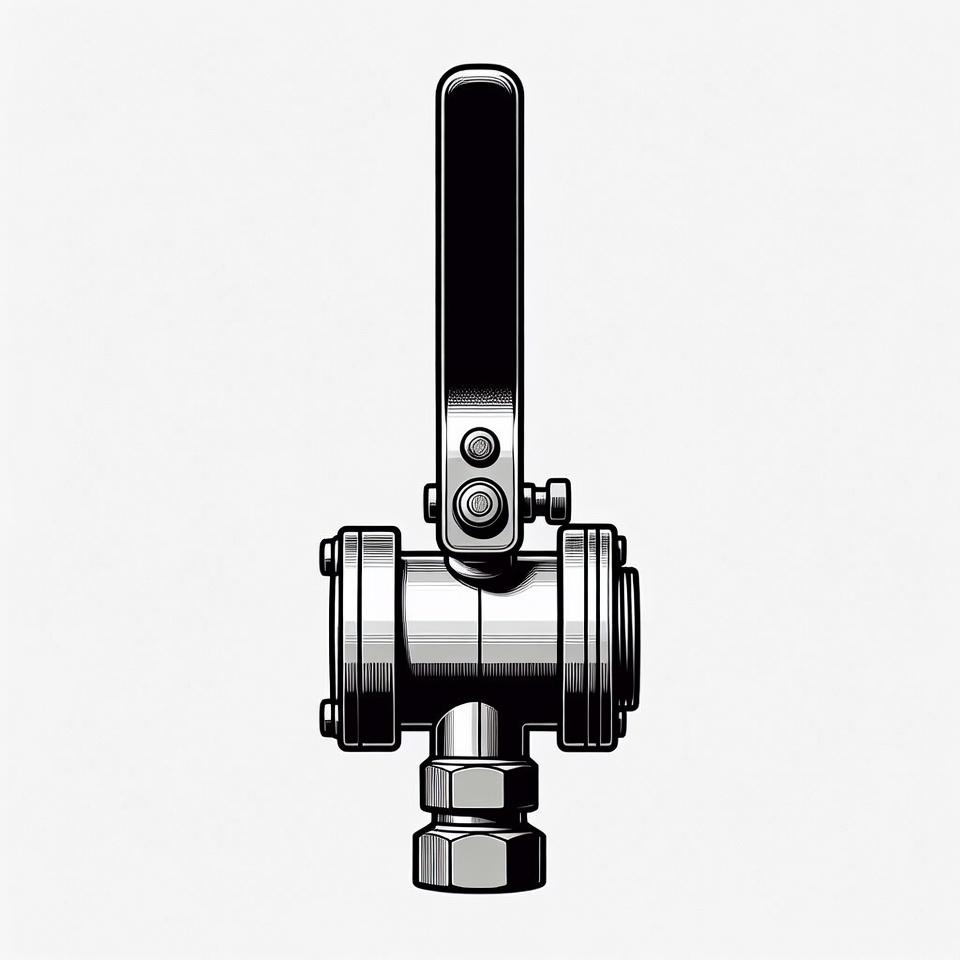

Bluefire Valve When should you replace it?

Not every worn part in a workshop draws attention but a single small fitting can change how a routine job ends. When technicians talk about threaded cartridges that connect to a burner or a refrigerant can they sometimes point to Bluefire EN417 Valve as the component you check first. That valve affects how securely a connection holds how easily it opens and whether a tool behaves the same way on the hundredth use as it did on the first.

Recognizing when a valve needs replacing begins with how it behaves in use. If a connection starts to feel loose when you screw a cartridge into a stove or when a can no longer hold pressure after a normal handling routine these are practical signals. Leaks at the joint or a valve that resists turning and then slips are not small annoyances. They increase waste and create safety headaches during routine jobs. Manufacturers that make valves to the EN417 reference aim for consistent thread fit and sealing to avoid those problems.

Wear can be subtle. Threads suffer from over torque and cross threading especially in adverse conditions like cold weather or when hands are gloved. Dust grit and residues from nearby work can accelerate wear and leave a valve that looks fine but does not perform. In workshops where gear is shared or where stock rotates quickly a valve can go from reliable to marginal before anyone files a complaint. Regular visual checks for deformation scoring or residue are quick tests that often catch a developing fault before it becomes an incident.

Another sign to watch for is inconsistent actuation. When a valve opens too easily and then closes slowly or when the dispense pattern changes during a single session the mechanism inside the fitting may be degrading. That change can come from seal fatigue contamination or tiny distortions in the valve face. For users who depend on a steady flow pattern to get a finish or a fill right this variability translates to frustration and rework. Replacing a suspect valve often restores predictable behavior without altering the tool.

Routine handling and storage matter for lifetime too. Valves that are repeatedly dropped or that sit in humid corrosive environments will age faster. Protective caps and simple storage routines keep threads cleaner and prevent knocks that dent the seating surfaces. For operations that ship or resell cartridges keeping valves capped and packed cushioned reduces returns and helps preserve safety margins. Many suppliers publish handling and inspection guidance which makes routine checks straightforward for procurement and floor staff.

When a valve shows visual damage or when leaks appear the replacement choice should match the original specification. The right threaded pattern and sealing type preserve tool compatibility and limit surprises on site. Opting for parts that meet recognized test routines for air tightness pressure and torque gives buyers confidence that the new fitting will behave as expected under normal use. Suppliers that emphasize testing and inspection report fewer field complaints because their parts meet the same fit expectations as the tools they mate with.

There are economic signals too. If a workplace sees higher than normal product waste or an uptick in returned units the hidden cost of a worn valve can show up quickly. Small recurring losses across many sites add up and they are less visible than a single catastrophic failure yet they undermine margins and staff patience. A light duty replacement program that pairs visual checks with a modest parts budget often yields calmer operations and fewer last minute rush orders.

Regulatory and public attention to safe handling and disposal has put more eyes on how consumables are stored and retired. Clear labeling and consistent valve quality reduce incidents during transport and at collection points. For organizations that manage multiple sites setting a standard for valve replacement and for how empty units are prepared for recycling reduces risk and simplifies training for staff who move between locations.

If you are responsible for maintenance or purchasing start with a short inspection plan. Check threads for scoring check seals for flattening and test actuation at ambient conditions. Keep a small supply of compatible replacements on hand and record failure modes so you can spot patterns. Those simple steps help teams respond before a marginal fitting becomes a stoppage.

Choosing a partner who documents production and inspection practices makes replacements easier to manage at scale. Suppliers that publish compatibility guidance and testing notes help procurement match parts to tooling and give floor teams confidence when they swap a fitting during service. For examples of valve styles and production notes visit the Bluefire site at https://www.bluefirecans.com/ .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness